Applications

Membrane technologies are versatile and essential across various industrial sectors. Here are some potential applications demonstrating their wide-ranging utility.

Biomass conversion and valorisation

Biogas is produced from decomposition of organic waste. Before being injected into the gas network, the biogas must be purified and upgraded. Regardless of the scale and process of biogas production, its purification represents a significant fraction of product cost and overall energy efficiency.

Application examples

- Biogas upgrading (methane purification)

- Improved electricity-gas separation (recycling of hydrogen, purification of methane)

Decarbonisation and reduction of CO2 foot print

A challenge for efficient CO2 capture processes is to reduce energy consumption and investment costs. In many processes studied for CO2 capture, membrane technology is recognized for its ease of installation and its compact design, energy efficiency, flexibility for operation and maintenance, and its ability to overcome thermodynamic limitations.

With changing standards and restrictions on CO2 emissions, increasing demands for disruptive CO2 capture technology offers an opportunity for deployment of membrane materials.

Application examples

- Intensification of post-combustion CO2 capture by chemical absorption in a gas-liquid membrane contactor

- Advanced CO2 gas separation membranes providing high selectivity for CO2 separation

- Direct Air Capture (DAC) : multistage membrane separation process for direct CO2 capture from the air

- Conversion of CO2 into biofuel by catalytic reaction in a membrane reactor

Separation of hydrocarbons and other process gases

A significant portion of total global energy consumption is due to hydrocarbon purification processes. Separation of olefins/paraffins (O/P), used for propylene or ethylene purification, is one of the most energy-intensive separation processes. Separation units using membrane technologies can provide highly efficient hydrocarbon purification by increasing process energy savings, maximizing product recovery and reducing process CO2 emissions.

Application examples

- Propylene purification (hybrids of distillation columns / replacement of C3 separators)

- Propylene recycling (flare gas, polypropylene reactors)

Recovery and efficient enrichment of specific gas compound

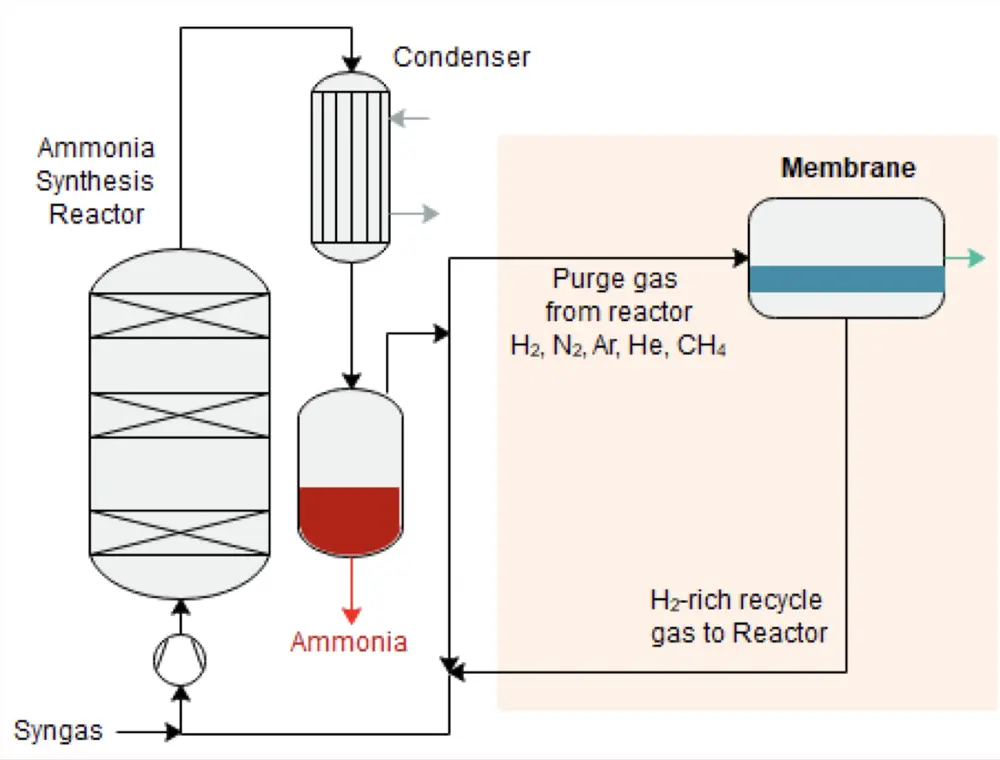

Membrane separation processes offer significant cost savings in hydrogen management for refineries and production plants, through the use of hydrogen-selective membrane materials. Tailor-made, compact and efficient units can be installed on existing installations. Potential applications cover a variety of refining processes with a wide range of compositions and operating conditions.

This principle also applies to other applications where the separation and purification of gas mixtures are problematic or complex (separation of mixture of O2/N2, helium, acid gas traces…).

Exemples d'applications

- H2 recovery from purge gas, e.g. from ammonia production

- Syngas H2 / CO ratio adjustment

- Production of ultrapure H2 (>99.99999%) thanks to highly selective palladium alloy membranes

- Purification of helium extracted from gas field

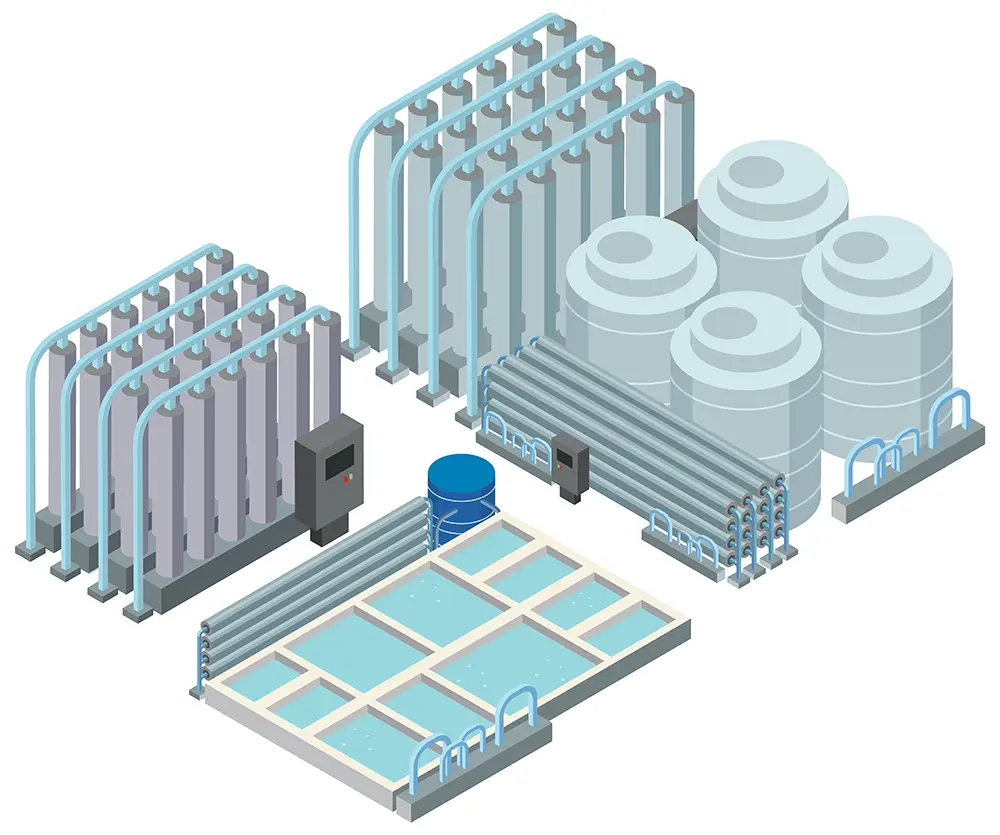

Water resources and discharges management

Membrane processes for water or aqueous effluents treatment are conventionally used in industry. These are non-destructive, continuous processes without addition of chemicals, and are used in fields as varied as agri-food, pharmaceuticals, or nuclear.

Application examples

- Treatment of effluents containing micropollutants/drug substances by nanofiltration or reverse osmosis

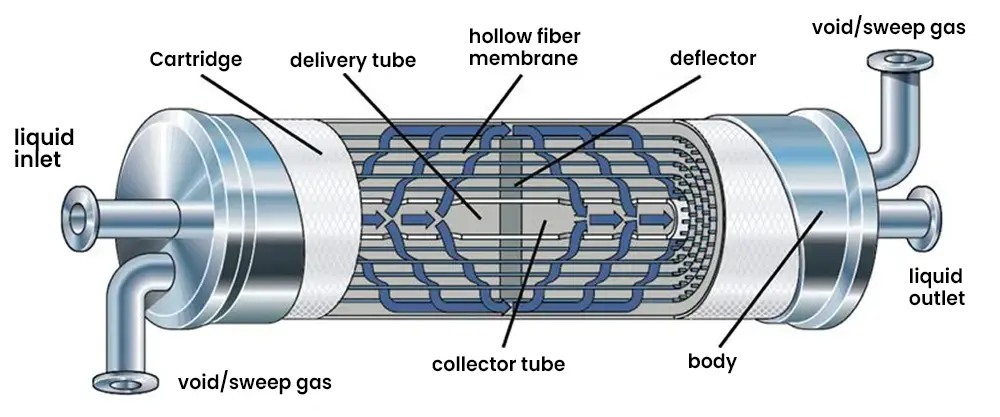

- Elimination of dissolved oxygen in primary effluents of nuclear power plants by degassing in a gas/liquid membrane contactor

- Transmembrane distillation for seawater desalination or aqueous effluents treatement