Softwares

We have flowsheeting software (PSE software) as well as powerful digital development tools, in order to offer you software solutions that meet your needs as closely as possible.

To design more efficient units, operate a highly integrated process as close as possible to its limits, and deal with new regulations (environment, safety, etc.), engineers can no longer content themselves with simple process models. They need a powerful but also easy-to-use tool to simulate plant behavior, quickly test new configurations and obtain an optimal solution without being modeling specialists.

Flowsheeting software (or PSE, such as the AspenTech® or ProSimPlus® software suite) meets these requirements by offering a complete, user-friendly, numerically stable environment and ensuring compliance with material and energy balances. Using these digital tools allows us to model any type of material transformation process, thereby helping industries improve their operational efficiency, reduce their carbon footprint, become more energy efficient, and make the most of available resources.

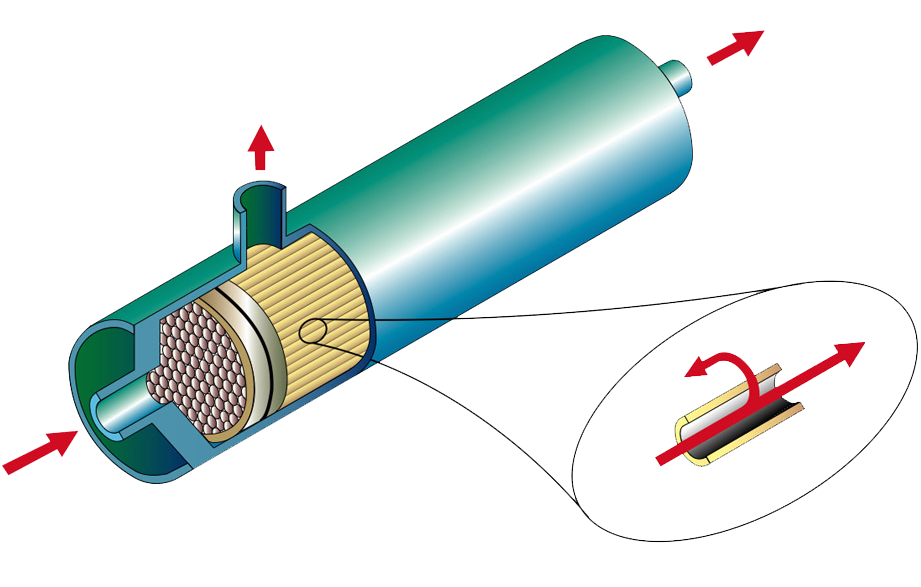

We have developed numerical tools to model multi-constituent separation of a gas mixture through a membrane module.

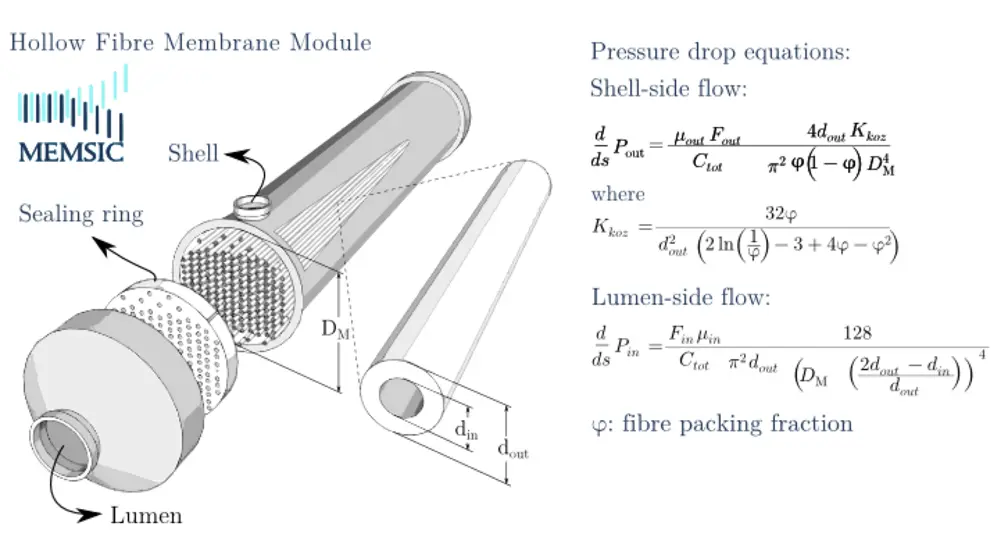

MEMSIC V2

Module V1 supplemented by the following specificities:

- Upstream and downstream pressure drop calculation

- Joule-Thomson effect: estimation of temperature variation caused by the pressure drop between membrane upstream and downstream sides

SWEEP