Services

MEMSIC addresses your needs through various adapted services.

We offer a range of services covering all stages of process development, from feasibility studies to industrial implementation.

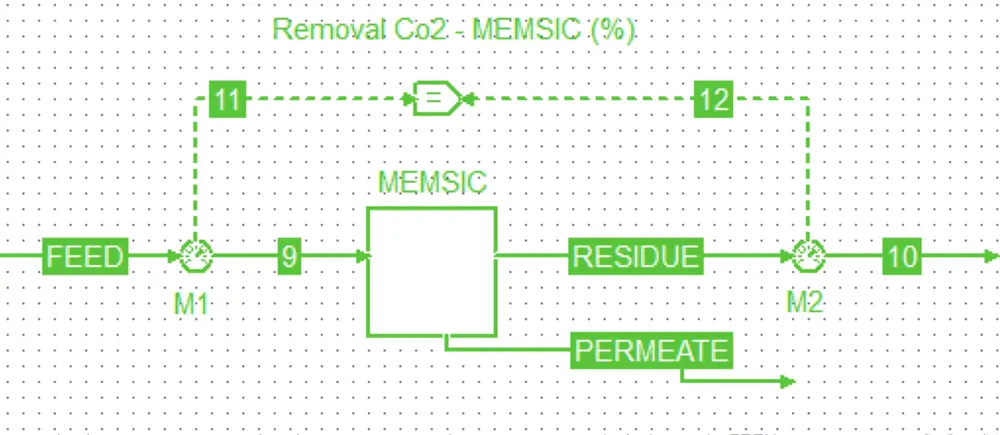

- Fluid separation modeling software for specific applications

- Unit operation for PSE software (ProSim®, AspenTech®, Pro/II®…)

- Digital optimization tools

- Identification of optimal process structures and associated operating conditions

- Optimization by numerical simulation based on Artificial Intelligence

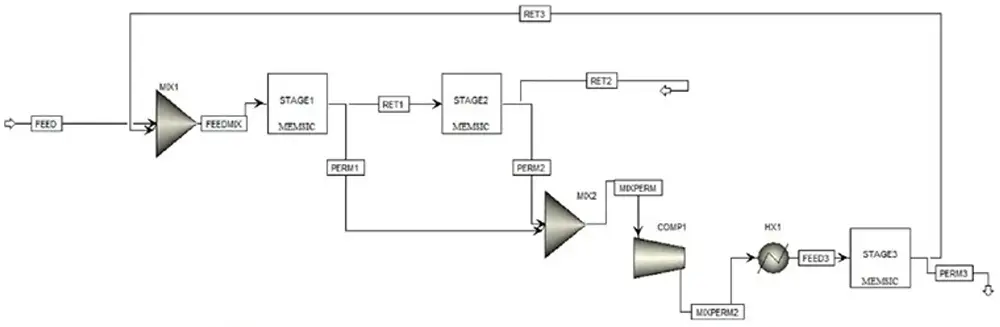

- Process modeling – Process Synthesis

- Dimensioning, choice of technologies and process diagrams

- Cost estimate (CAPEX/ OPEX)

- Economic and environmental analysis

- Market research, technology watch, technical-economic study

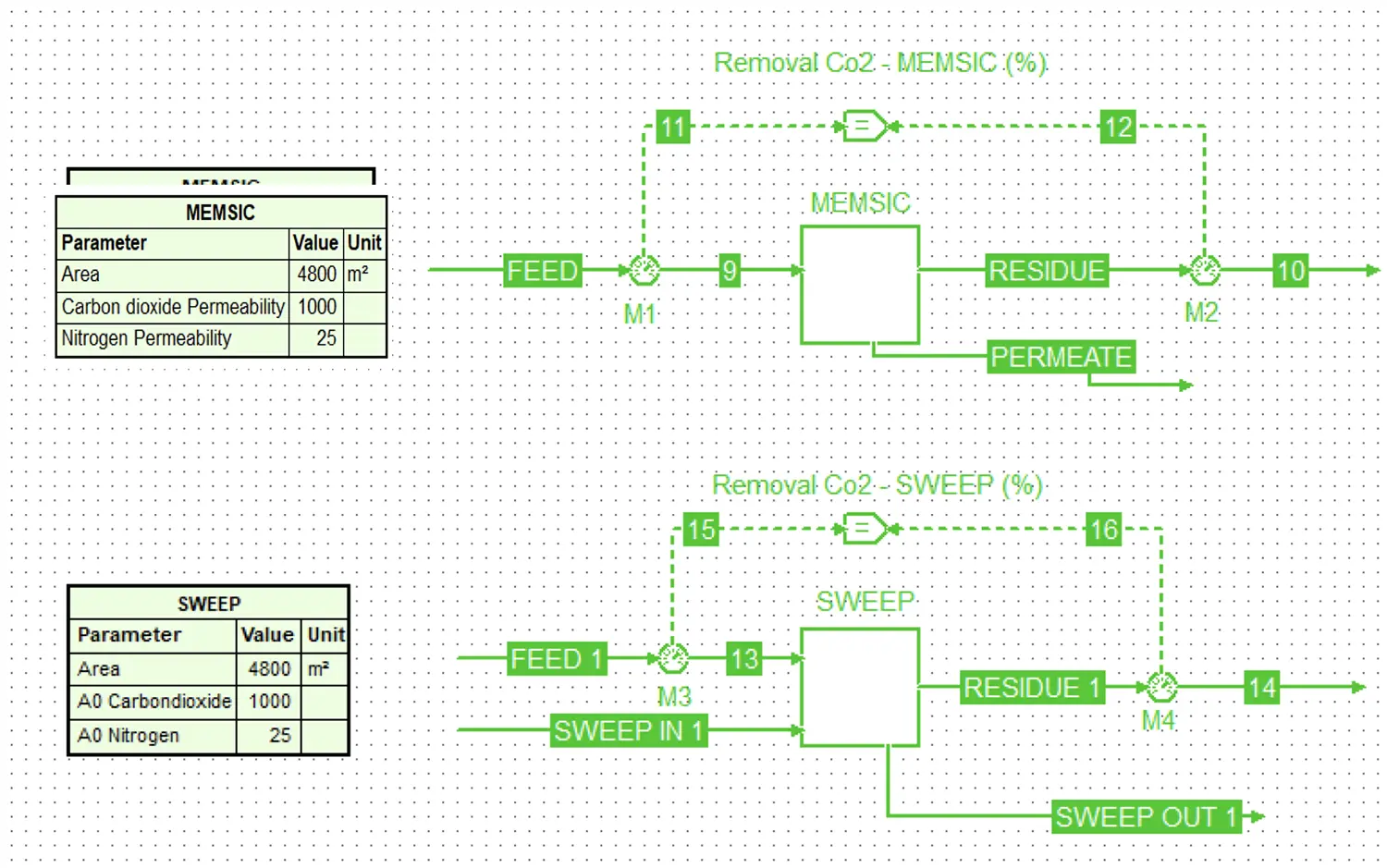

Example of completed project #1

Goals

Separate a mixture of gases

- Select the right materials

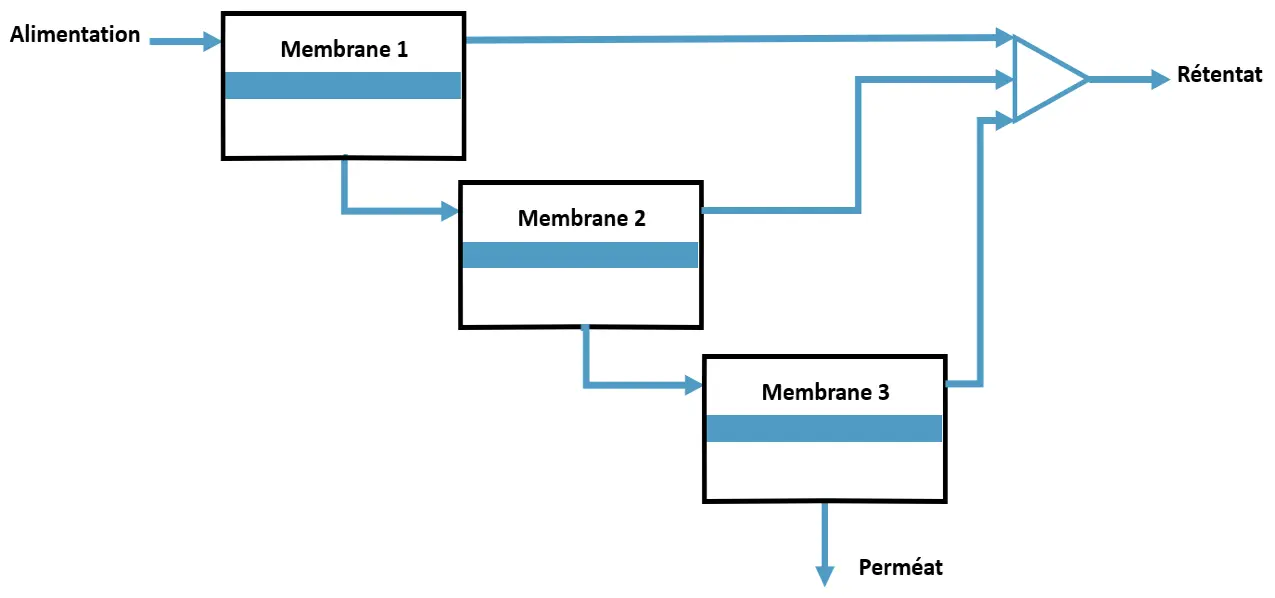

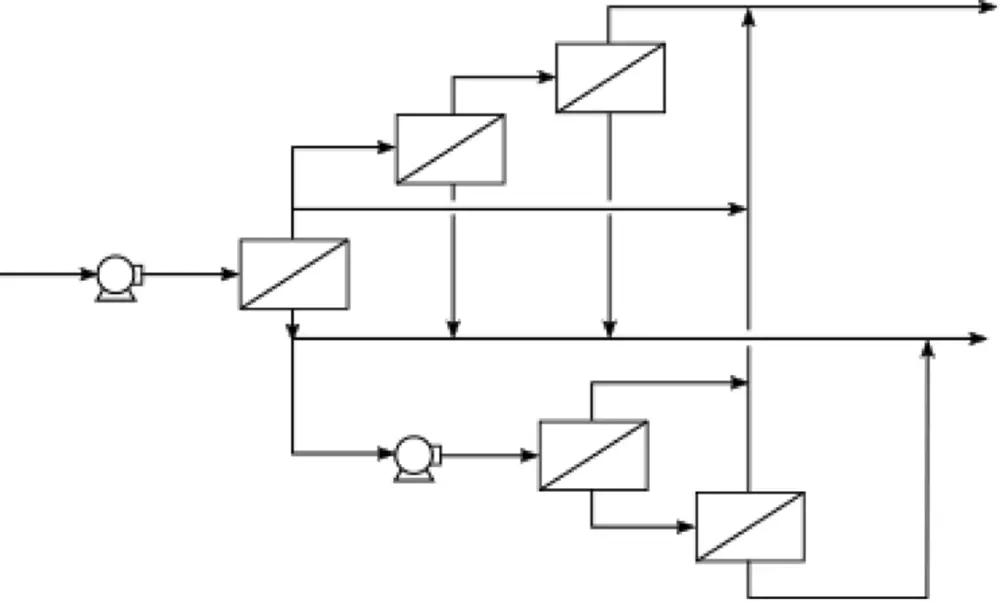

- Sizing and modeling membrane stages

Definition

How to choose the best membrane technologies?

Compare different membrane types and configuration.

Specify the cost function with viable economic parameters.

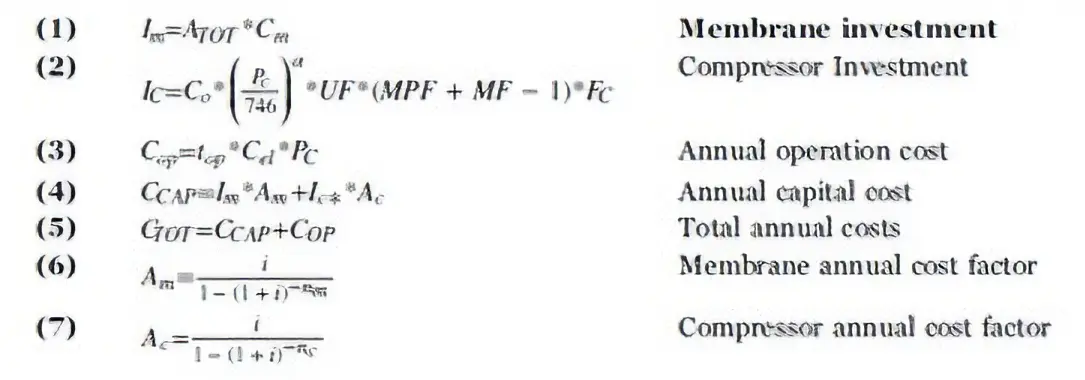

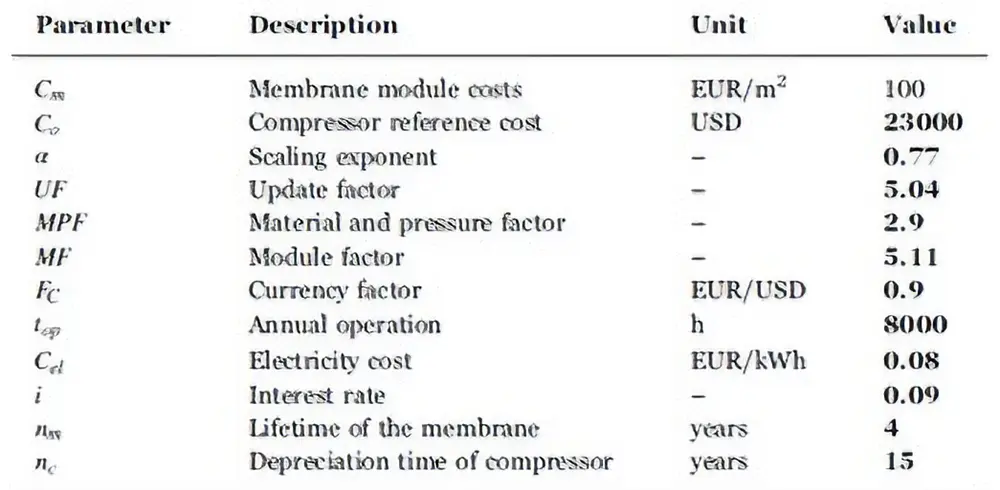

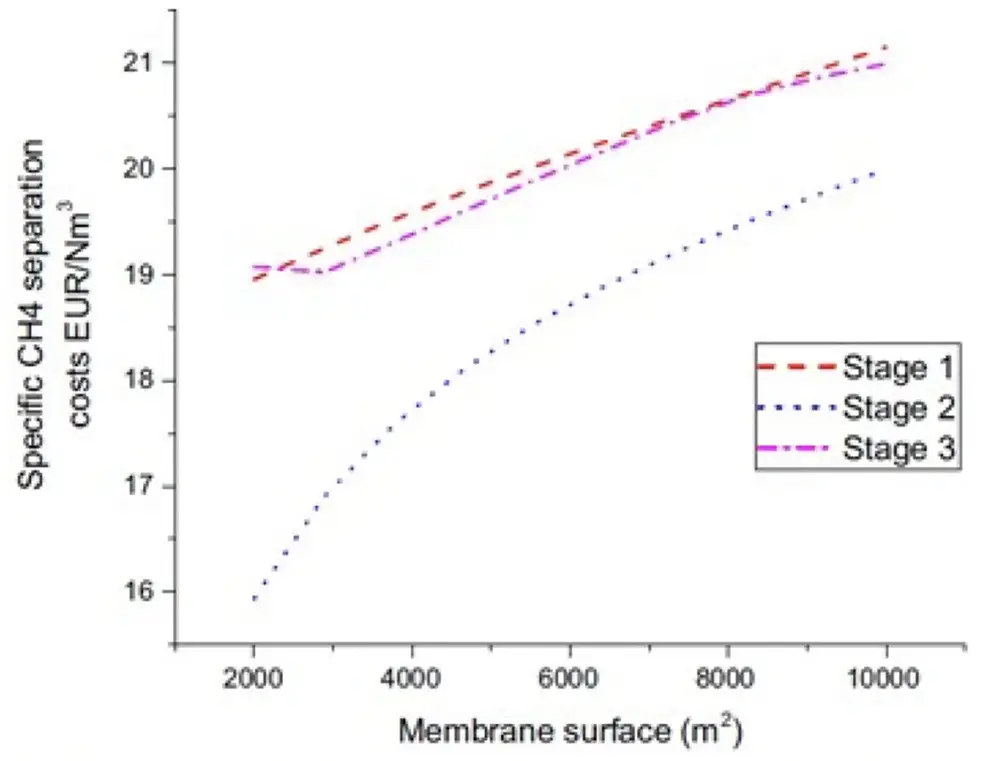

Example of completed project #2

Goals

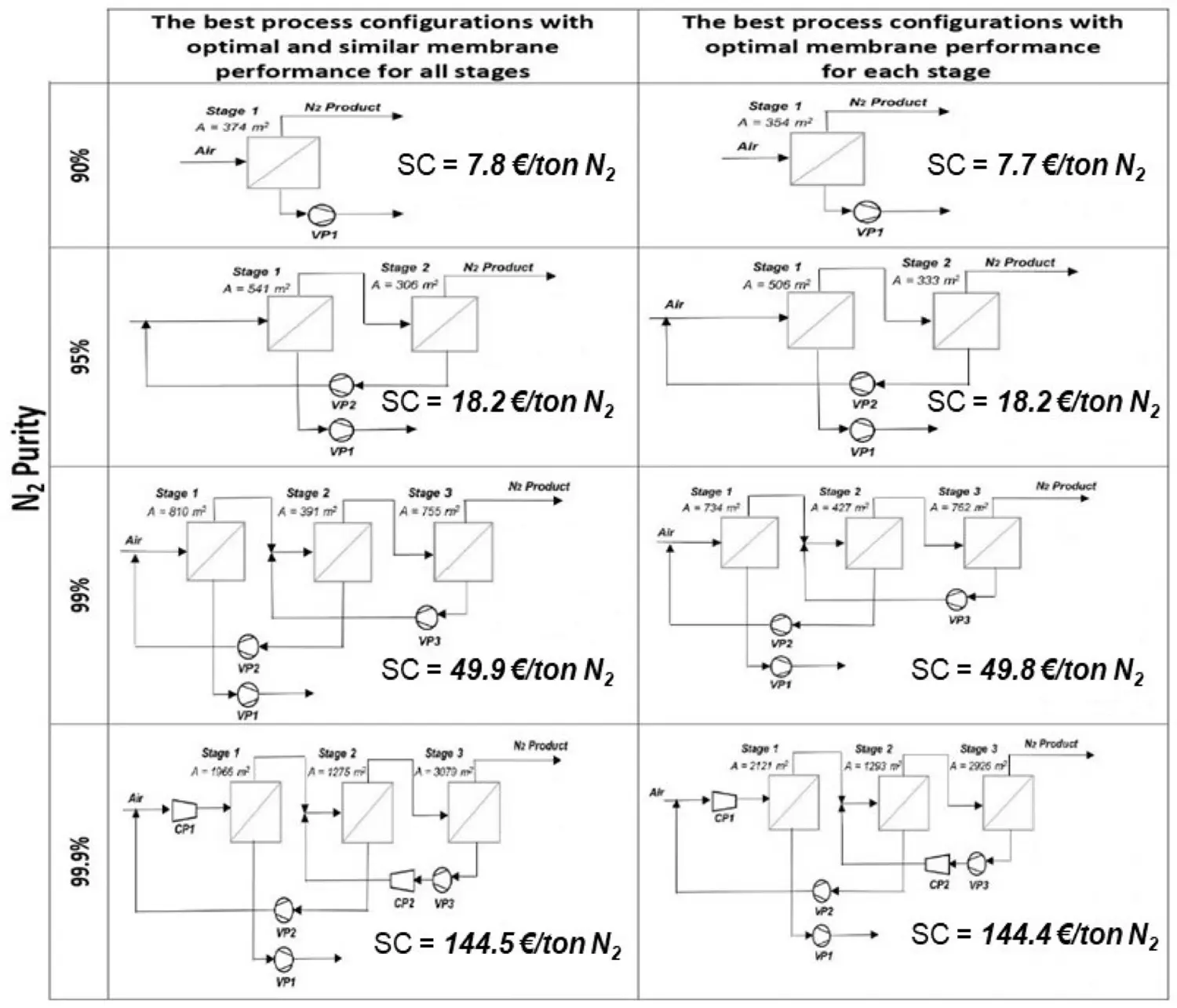

Separate a mixture of O2/N2

- Minimize the cost: CAPEX/ OPEX

- Maximize purity and recovery rate

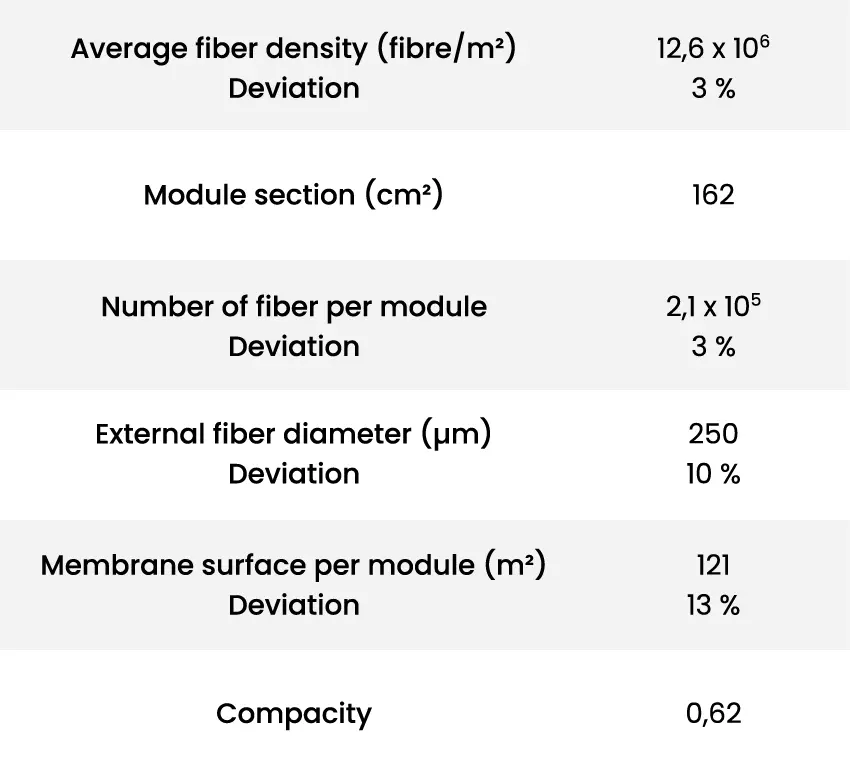

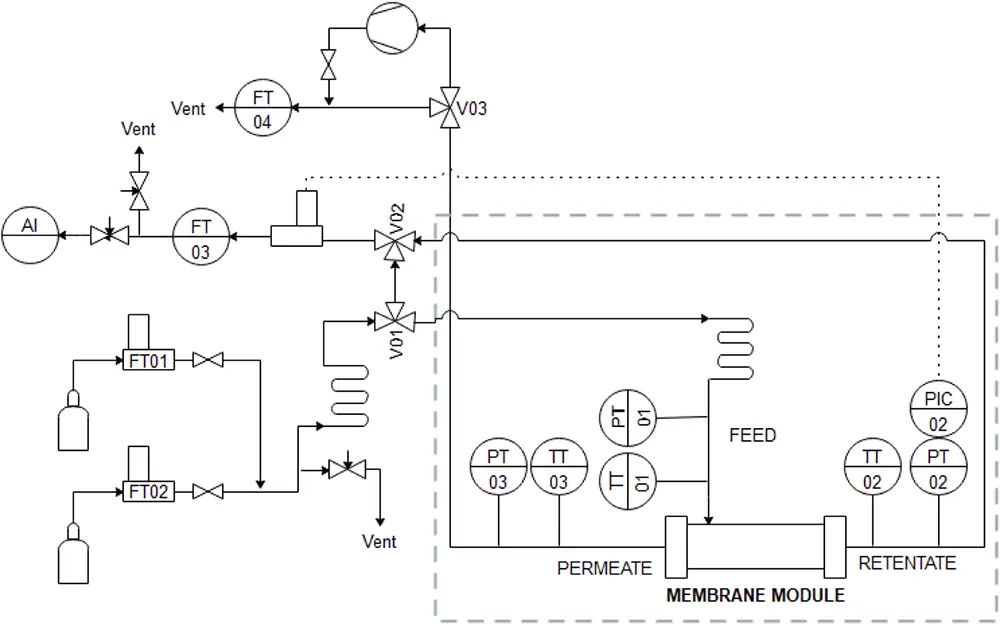

- Experimental setup for “Time Lag” method: measurement of permeability, diffusion, solubility parameters

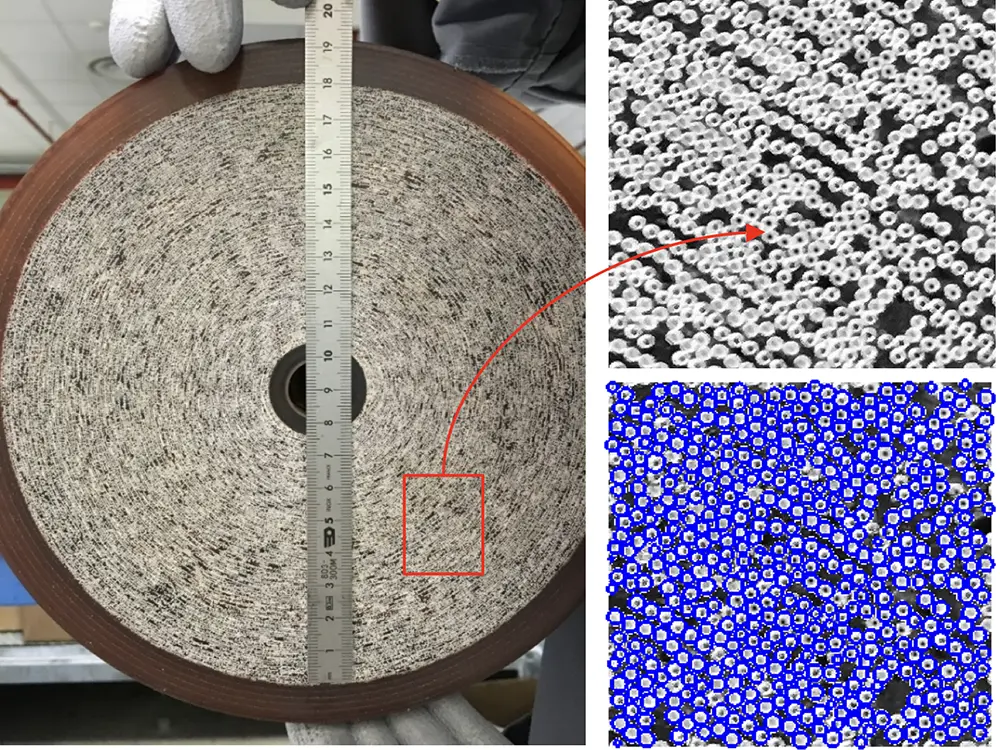

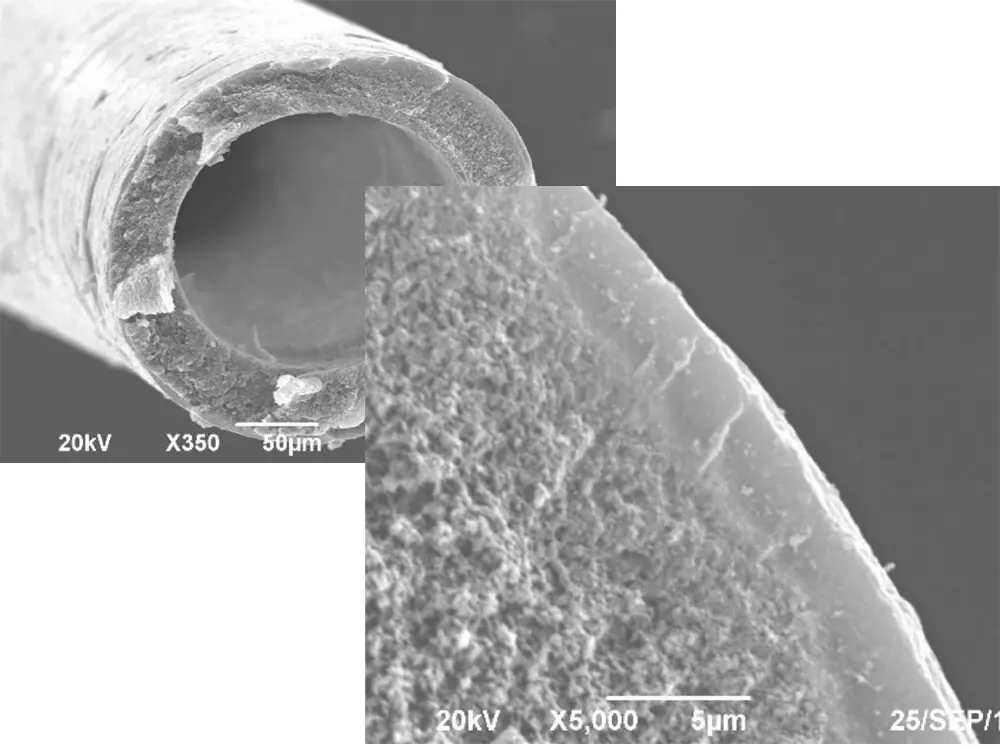

- Fiber counting by image analysis

- Scanning electron microscopy (SEM)

- Data acquisition on experimental pilot units

- New materials or commercial membranes

- Retro-modeling with respect to experimental points (MEB)

Example of completed project

Goals

Already existing unit of a membrane separation process whose characteristics are unknown

- Characterize the membrane

- Model the unit and optimize its operating conditions

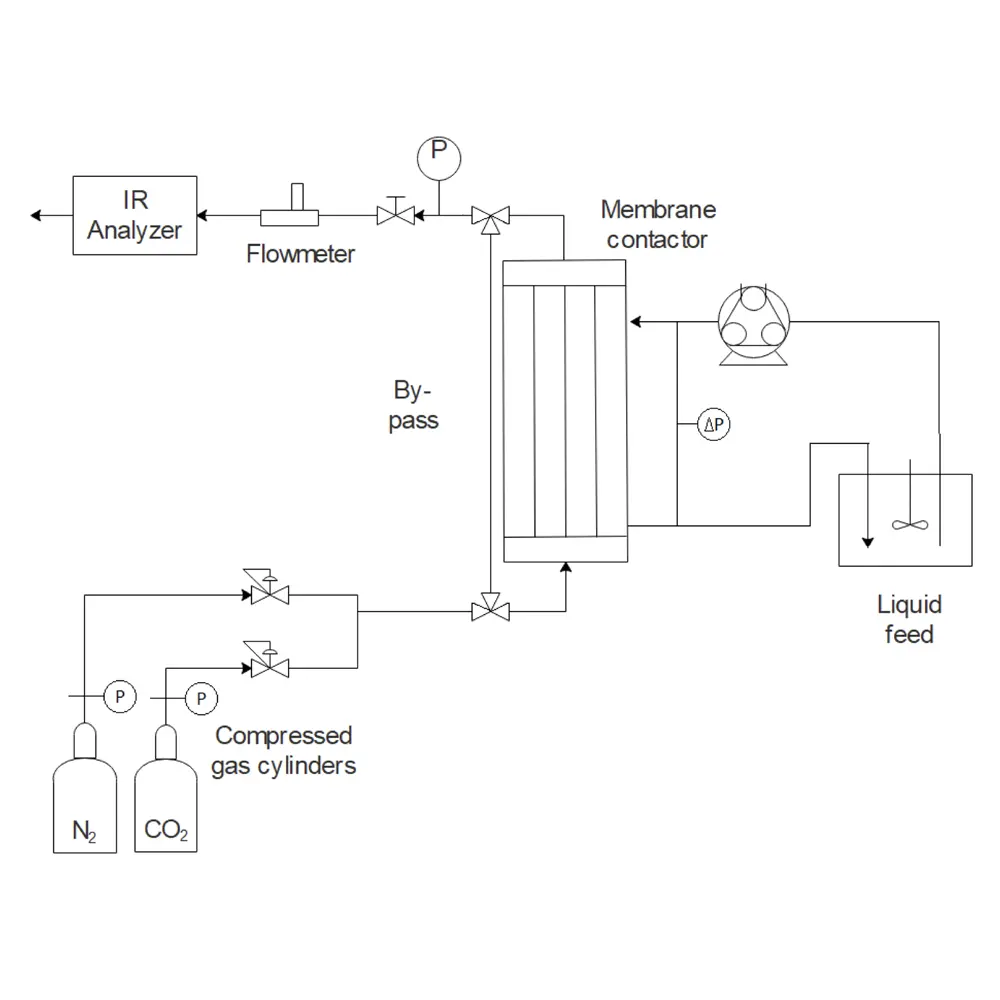

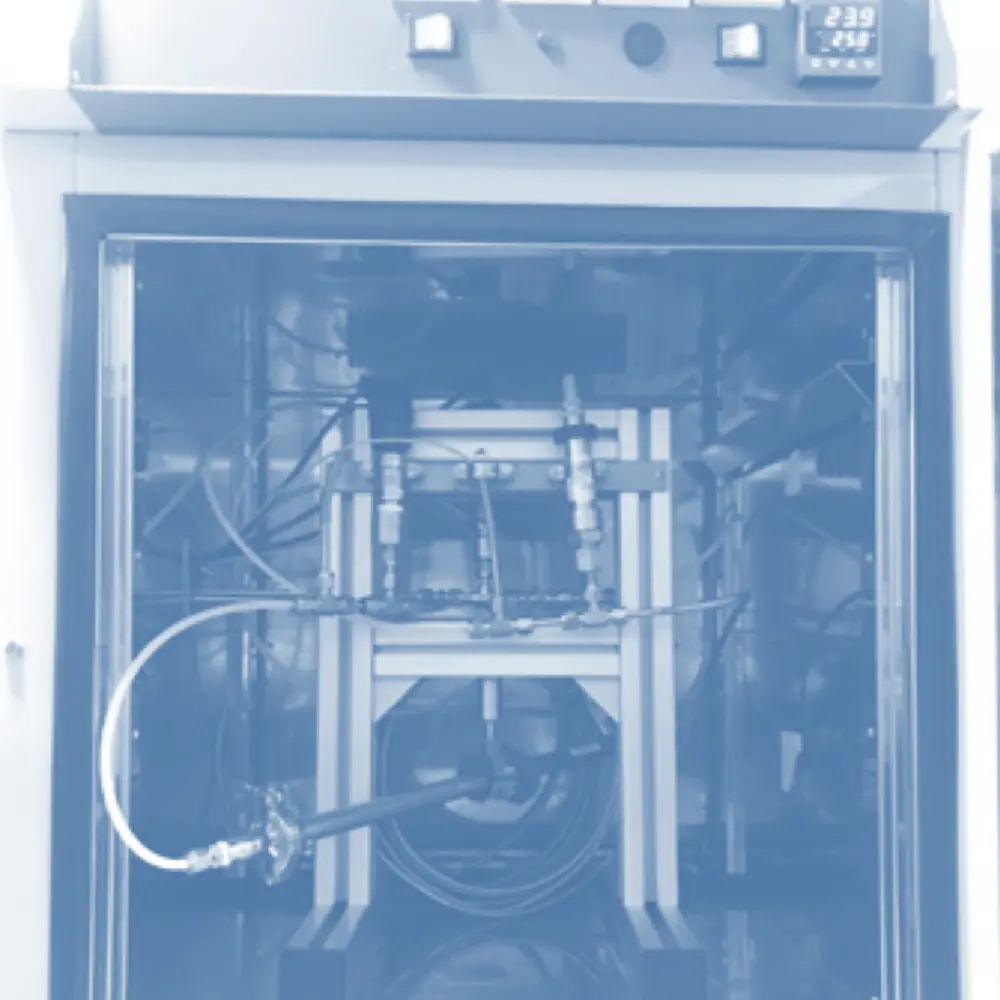

- Wide range of laboratory equipment and pilot available (absorption by membrane contactor, gas permeation, membrane distillation, degassing by membrane contactor, reverse osmosis)

- Analytical means (infrared spectroscopy, gas phase chromatography, katharometer, etc.)

- Design of test setup and pilot units

- Data acquisition

- Laboratory-scale experimental validation

- Process feasibility

Example of completed project

Goals

Already existing unit of a membrane separation process whose characteristics are unknown

- Characterize membrane

- Model the unit and optimize its operating conditions

Data acquisition

- Software training and associated processes

- Assistance